Cathodic Protection Measurement

Key Benefits

Maintain safety

Prevent failures that could lead to injury, environmental harm, or asset loss.

Regulatory compliance

Meet statutory obligations under frameworks like the UK’s HSE or Norway’s PSA.

Support life extension

Identify aging mechanisms and plan maintenance or upgrades.

Validate barriers

Confirm that structural elements remain effective as part of the safety-critical barrier system.

Aligned With Class and Integrity Campaigns

Supports Special Periodic Survey (SPS) & Risk Based Inspection (RBI), and corrosion programs by confirming anode coverage and coating condition in the field.

Delivered by Certified Divers or Shallow ROV Systems

Reliable readings from calibrated reference electrodes, executed under safe access protocols with traceable output.

Cathodic Protection Measurement

Service Description

We perform in-water cathodic protection measurement services for floating structures. We acquire cathodic protection potential readings using diver-held or ROV-mounted reference probes to verify the performance of sacrificial anode systems on FPSOs, semi-submersibles, and floating wind platforms.

These measurements help asset owners understand whether submerged steel remains within the protected voltage range and identify zones that may require further action.

Read more

Cathodic protection is a critical part of corrosion control for offshore assets. SubseaPartner provides localized cathodic protection readings using a Bathycorrometer on hull plating, structural supports, and anodes. These readings determine whether structures are within target protection thresholds.

We acquire CP potentials on:

- FPSO hull plating, bilge keels, fairleads, and padeyes

- Semi-submersible braces, pontoons, and structures

- Floating wind platform columns and outfitting features/Steel pontoons and external outfitting on floating wind platforms

Execution methods include:

Diver-deployed Bathycorrometer

Multi-point logging across structural surfaces and near anode clusters

Documentation of voltage values mapped to inspection zones

Use cases:

Special Periodic Survey or class survey support

Cathodic protection status checks during IMR campaigns

Follow-up to visual anode degradation

Confirmation of cathodic protection levels after retrofit or maintenance

Localized risk tracking in weld or coating damage zones

SubseaPartner provides clear, traceable reports including pass/fail indicators and all supporting data for engineering review.

What to expect:

Calibrated measurement of your asset’s cathodic protection levels, delivered with documentation, expert analysis, and no disruption to operations.

Operational Scenario

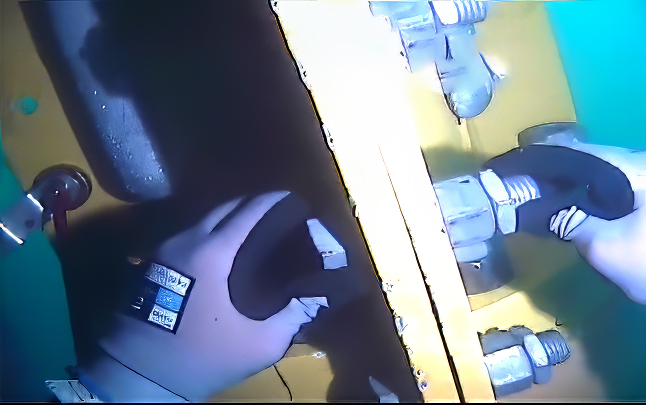

Real Results: Perform cathodic protection survey on FPSO turret bend stiffener connectors

Challenge

SubseaPartner were asked by a client to carry out a cathodic protection survey on FPSO turret bend stiffener connectors due to low readings reported by ROV. SubseaPartner mobilized a dive team equipped with calibrated Bathycorrometers to log CP values within the turret system.

Outcome

Inspection indicated compromised cathodic protection with broken continuity cabling & 100% depletion on 95% of the anodes. SubseaPartner engaged with a specialist supplier to manufacture new cables and design a bolt on anode replacement. These were installed the following year. These solutions restored cathodic protection values to within acceptable norms.

Let’s Secure Your Operations

Get in touch with SubseaPartner’s experts for certified subsea services. We provide safe, class-compliant solutions, technical support, and reliable guidance to extend offshore asset integrity.